Unlock the Key Advantages of Concrete Scanning for Streamlined Operations and Cost Savings

In the realm of building and framework development, the use of concrete scanning technology has actually changed project monitoring methods. By incorporating innovative scanning strategies, firms can attain unequaled accuracy and efficiency in their operations. From boosting task preparation and execution to lessening disturbances and downtime, the advantages of concrete scanning are complex. It is not just the surface-level advantages that make this innovation vital. Real value lies in the nuanced methods which concrete scanning can transform the landscape of building jobs, resulting in streamlined procedures and significant cost financial savings.

Boosted Task Preparation and Execution

Boosted task preparation and execution are essential parts in the successful execution of concrete scanning modern technology within building and construction projects. By integrating concrete scanning into the first project preparing stage, construction groups can accurately identify the place of rebar, post-tension wires, and other embedded objects within concrete structures. This info permits more exact task organizing, lowering the danger of pricey errors or hold-ups throughout the building procedure.

Moreover, with concrete scanning innovation, job managers can produce in-depth 3D designs of the subsurface conditions prior to any type of exploration or reducing occurs. This level of understanding makes it possible for service providers to make informed choices and changes to their building plans, resulting in enhanced project performance and total top quality.

In essence, the integration of concrete scanning improves task planning by providing critical data that improves decision-making procedures, lessens rework, and makes certain that construction projects are completed on time and within budget. By leveraging this sophisticated innovation, building and construction teams can enhance operations, mitigate dangers, and supply effective outcomes for their clients.

Increased Accuracy in Object Detection

By integrating concrete scanning innovation into building and construction tasks, the focus changes in the direction of achieving raised precision in object discovery, especially in recognizing rebar, post-tension cables, and other ingrained items within concrete structures. By specifically recognizing ingrained objects, building and construction teams can avoid costly mistakes, revamp, and job delays.

Concrete scanning technology allows building and construction professionals to envision the inner make-up of concrete frameworks in real-time, providing comprehensive insights right into the visibility and positioning of things within the concrete. This level of precision not only boosts task planning and implementation but likewise reduces the risk of crashes and structural failures. With enhanced things detection capacities, building groups can function much more effectively, decrease product wastefulness, and eventually supply high-quality jobs within budget and schedule restrictions.

Improved Safety and Danger Reduction

In addition, concrete scanning help in making certain the structural security of structures and infrastructure by finding gaps, delamination, or various other problems that might compromise the safety of the project. By addressing these problems beforehand, building and construction groups can take the needed rehabilitative activities to strengthen the concrete and avoid future problems. Inevitably, the enhanced safety and risk mitigation supplied by concrete scanning innovation not only guard the health of employees and the public however also add to the general success and durability of construction jobs.

Time Efficiency and Price Financial Savings

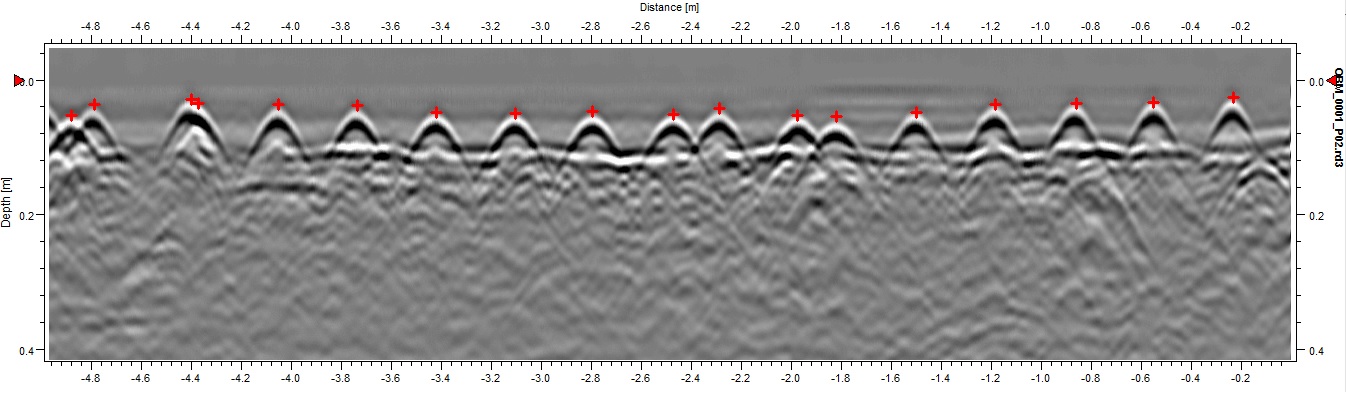

Carrying out concrete scanning innovation in building jobs can cause significant time effectiveness and cost financial savings. By utilizing sophisticated scanning tools such as ground-penetrating radar (GPR) and electromagnetic induction, building and construction teams can properly locate rebar, post-tension cords, and various other subsurface components without the demand for devastating approaches. This precise information enables structured job planning and execution, reducing the time invested in unforeseen hold-ups because of striking unidentified objects throughout excavation or exploration.

Furthermore, the capability to recognize potential threats underneath the surface in advance can protect against costly damages to tools and injuries to workers, further adding to general price savings. In addition, the performance acquired from making use of concrete scanning technology converts right into faster project conclusion times, making it possible for construction business to handle more projects and increase their earnings.

Lessened Disruptions and Downtime

The use of concrete scanning modern technology not only improves time performance and cost savings in building and construction jobs however additionally plays an important role in decreasing disruptions and downtime. By employing sophisticated scanning techniques such as Ground Passing Through Radar (GPR) or Concrete X-ray, building groups can properly situate rebar, post-tension cords, avenues, and other subsurface frameworks within concrete structures without the demand for damaging investigative methods (RainierGPR Concrete imp source Scanning). This precision her latest blog in locating crucial parts aids prevent accidental damages throughout exploration, cutting, or coring tasks, hence dramatically minimizing the risk of unforeseen downtime due to repair work or revamp

Additionally, concrete scanning makes it possible for project managers to intend building tasks extra effectively by recognizing possible barriers in advance. Eventually, the minimized disturbances and downtime promoted by concrete scanning innovation lead to boosted job timelines, boosted productivity, and overall expense savings for building jobs.

Conclusion

To conclude, concrete scanning uses numerous advantages for streamlined procedures and expense savings in different industries - RainierGPR Concrete Scanning. By improving job preparation and execution, enhancing accuracy in things discovery, enhancing security and danger reduction, saving time and expenses, and reducing disturbances and downtime, companies can optimize their processes and achieve higher effectiveness. Overall, including concrete scanning into operations can result in enhanced end results and a much more productive workplace

By incorporating concrete scanning right into the preliminary project intending stage, building and construction teams can properly recognize the place of rebar, post-tension cables, and various other embedded things within concrete frameworks.By incorporating concrete scanning innovation right into building tasks, the emphasis moves towards achieving enhanced precision in object discovery, especially in identifying rebar, post-tension cords, and other ingrained items within concrete frameworks.Concrete scanning innovation allows building and construction professionals to envision the interior make-up of concrete structures in real-time, browse around this web-site offering thorough understandings right into the visibility and positioning of things within the concrete. By utilizing innovative scanning methods such as Ground Penetrating Radar (GPR) or Concrete X-ray, building and construction teams can properly situate rebar, post-tension cords, avenues, and various other subsurface structures within concrete structures without the demand for harmful investigative methods. Ultimately, the lessened interruptions and downtime helped with by concrete scanning modern technology lead to improved job timelines, increased performance, and overall expense savings for building jobs.